These tiny wrinkles in ultra-thin materials hold a secret power that engineers have debated for decades – now we finally know the truth.

Imagine a material so thin it’s just a few atoms thick, yet stronger and more flexible than you’d ever expect. Now imagine that the tiny ripples on its surface – invisible to the naked eye – could be the key to creating everything from better electronics to artificial skin.

Materials scientists have long been fascinated by the mysterious properties of ultra-thin materials. When sheets of material become extremely thin – just nanometers thick (that’s billionths of a meter) – they naturally develop ripples, similar to how a piece of plastic wrap crinkles when stretched. For decades, scientists have debated exactly how these ripples affect the material’s properties, with competing theories offering conflicting explanations.

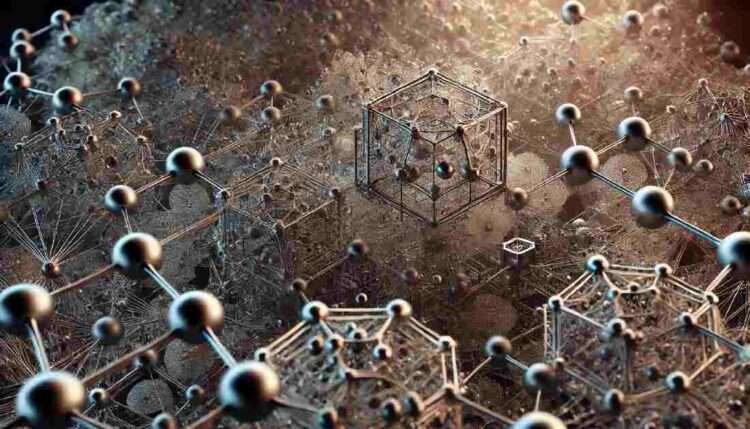

Now, researchers have settled this long-standing controversy by demonstrating that these tiny ripples fundamentally transform how these materials behave, creating what they call “disordered metamaterials” with properties that can be customized for specific applications.

The Mystery of the Rippling Effect

The research, published in the Proceedings of the National Academy of Sciences (PNAS), combined theoretical modeling with innovative experimental approaches to solve a puzzle that has confounded scientists for years.

“Thermally induced ripples are intrinsic features of nanometer-thick films, atomically thin materials, and cell membranes, significantly affecting their elastic properties,” the study explains. These ripples appear naturally in extremely thin materials due to thermal fluctuations – the random movement of atoms caused by heat.

What makes this research groundbreaking is that it definitively shows these ripples create materials with “scale-dependent elasticity” – meaning their mechanical properties change depending on the size of the material. This contradicts classical elasticity theory, which predicts that material properties should remain constant regardless of size.

To investigate this phenomenon, the researchers developed an ingenious method. They created nanometer-thick films with precisely controlled frozen random ripples that mimic the natural thermal ripples found in ultra-thin materials. This allowed them to study the ripple effects in isolation, something previous researchers hadn’t been able to do.

The Experiment: Freezing Thermal Ripples in Time

The team used semiconductor manufacturing processes to create cantilevers (tiny diving board-like structures) made of aluminum oxide (Al₂O₃) that were just 28 nanometers thick – roughly 3,500 times thinner than a human hair. Some cantilevers were made with smooth surfaces, while others incorporated frozen random ripples.

By measuring how these structures vibrated at resonant frequencies, the researchers discovered that the rippled cantilevers behaved very differently from their smooth counterparts. The rippled versions showed enhanced bending rigidity – they were stiffer than expected – and this effect increased with the width of the cantilever.

Even more surprising was the discovery that identical rippled structures showed significant variations in their mechanical properties. Two cantilevers with exactly the same dimensions and manufactured in the same way performed differently because of the specific pattern of ripples on their surfaces.

“All the tested rippled cantilevers have the same geometrical dimensions and average random height profile, but their resonance frequencies are significantly different,” the researchers noted.

Scale-Dependent Properties: Breaking the Rules of Classical Physics

What makes these findings so revolutionary is that they contradict the principles of conventional elasticity theory that engineers have relied on for centuries. In traditional materials, properties like bending rigidity remain constant regardless of the material’s dimensions. But in rippled nanomaterials, the researchers found that bending rigidity increased with width, decreased with thickness, and remained independent of length.

The team developed a theoretical framework that accurately predicted these behaviors. When ripples are large compared to the film thickness, they effectively “renormalize” and increase the bending rigidity due to complex interactions between different ripple patterns.

This scale-dependent behavior opens up entirely new possibilities for designing materials with customized properties. By controlling the ripple patterns and dimensions, engineers could create materials with precisely tailored mechanical responses.

From Theory to Application: Designer Materials

The researchers didn’t stop at understanding the phenomenon – they demonstrated practical applications by creating novel mechanical structures with properties impossible to achieve using conventional smooth materials.

In one experiment, they created square cantilevers with varying numbers of cuts along their length. While the smooth cantilevers showed consistent bending regardless of the number of cuts, the rippled versions displayed dramatically different behaviors depending on the cut pattern. This allowed the team to program specific mechanical responses simply by changing the geometry of the cuts.

Taking this concept further, they constructed a “waterlily flower” microstructure that could fold into different 3D configurations based solely on the pattern of cuts in the 2D rippled material. They also created mechanical metamaterials with “delayed buckling” – structures that could withstand greater deformation before bending out of shape.

“The results presented in this manuscript demonstrate that thin films with thermal-like frozen ripples have unique mechanical properties that cannot be described with the well-known Hookean thin-plate theory,” the researchers concluded. “These materials represent a class of metamaterials that exhibit enhanced bending rigidity, strongly scale-dependent elastic parameters, and sample-to-sample variations proportional to the size of the structures.”

Why This Matters: The Future of Nano-Engineering

The implications of this research extend far beyond academic interest. Understanding how ripples affect ultra-thin materials could lead to breakthroughs in numerous fields:

- Flexible Electronics: As electronic devices become increasingly flexible and wearable, engineers need precise control over the mechanical properties of ultra-thin materials. This research provides a roadmap for creating materials with customized flexibility.

- Biological Interfaces: Cell membranes naturally exhibit ripples similar to those studied in this research. Understanding how these ripples affect mechanical properties could lead to better artificial skin, tissue engineering, and biomedical devices.

- Aerospace and Transportation: Ultra-lightweight materials are crucial for efficient transportation. Materials designed with controlled rippling could provide enhanced strength-to-weight ratios for applications in aerospace and automotive industries.

- Metamaterials: The ability to create materials with tailored mechanical properties opens up possibilities for exotic metamaterials with behaviors not found in nature.

What makes this research particularly exciting is its scalability. The team developed fabrication techniques that could be implemented using standard semiconductor manufacturing processes, suggesting that these designer materials could move relatively quickly from the laboratory to real-world applications.

The Bigger Picture: Disorder as a Feature, Not a Bug

One of the most fascinating aspects of this research is how it transforms what might be considered a defect – random rippling – into a valuable feature that can be harnessed for engineering purposes.

This approach mirrors a growing trend in materials science where researchers are finding ways to use disorder and imperfection advantageously rather than fighting against them. The paper specifically mentions “many functionally efficient but structurally disordered biological materials such as the hierarchical organization of trabecular bones and the cell organization of carnivorous plants” as inspiration.

By embracing and controlling disorder at the nanoscale, engineers may be able to create a new generation of materials that combine the best aspects of natural and synthetic systems – materials that are simultaneously strong, flexible, lightweight, and tailorable to specific applications.

As our technology continues to shrink and our demands for specialized materials grow, understanding phenomena like ripple-induced scale-dependent elasticity will become increasingly important. This research not only resolves a decades-old scientific controversy but also opens the door to an entirely new approach to materials design – one that works with, rather than against, the natural tendency of ultra-thin materials to ripple.

The tiny wrinkles that form spontaneously in nanometer-thick films might seem insignificant at first glance, but they could hold the key to the next generation of advanced materials that power everything from space exploration to medical implants.